Description

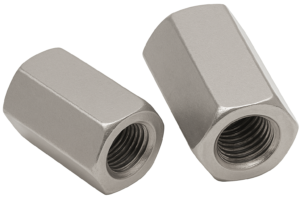

Hex weld nuts are a six-sided, internally threaded fastener with three triangular weldable projections on the top surface of every other corner of the fastener. The threaded hoe runs through the centre and has a pilot for the entire circumference of the opening which extends above the top surface of the nut and the above projections. The remainder of the top surface of the nut is flat.

We have a ready range of Hex Weld Nuts.

Characteristics of Hex Weld Nuts

Hex weld nuts have several distinctive features that make them suitable for different applications:

- Hexagonal Shape – The six-sided design provides excellent grip and stability, ensuring that the nut does not rotate when tightened.

- Projection Points or Tabs – Many hex weld nuts feature small projections or tabs that help create a strong fusion with the base metal when welded. These projections ensure proper placement and strong bonding.

- Threaded Interior – The internal threading allows for secure engagement with a bolt, creating a durable and reusable fastening system.

- Flange or Base Surface – Some hex weld nuts have an integrated flange to increase surface contact, enhancing load distribution and strength.

- Material Composition – These nuts are typically made from carbon steel, stainless steel, or alloy steel, depending on the application’s strength and corrosion resistance requirements.

Types of Hex Weld Nuts

Hex weld nuts come in various designs to suit different welding methods and application needs:

- Standard Hex Weld Nuts – These have a basic hexagonal shape with projection points for easy welding.

- Flanged Hex Weld Nuts – These nuts include an integrated flange for better load distribution and increased holding power.

- Pilot Hex Weld Nuts – These have an extended cylindrical pilot section that aids in positioning and alignment before welding.

- Self-Locating Hex Weld Nuts – Designed with locating features that ensure precise placement without additional alignment tools.

Applications of Hex Weld Nuts

Hex weld nuts are used in various industries for their strength and efficiency. Some common applications include:

1. Automotive Industry

- Used in chassis, engine mounts, and body panels for secure fastening.

- Helps in assembling vehicle frames and structural components.

2. Aerospace Industry

- Applied in aircraft structures where vibration-resistant fastening is essential.

- Provides reliable attachment points for critical components.

3. Construction Industry

- Utilized in steel frameworks, bridges, and heavy equipment.

- Ensures long-lasting connections in load-bearing structures.

4. Industrial Machinery

- Commonly found in conveyor systems, machine frames, and hydraulic assemblies.

- Helps secure heavy-duty components with precision.

5. Electronics and Appliances

- Used in the manufacturing of enclosures, electrical panels, and appliance casings.

- Ensures firm connections in compact designs.

Reviews

There are no reviews yet.